We all know that high-end cars are very expensive.In fact, high-end cars have expensive reason, take a car hub for example, high-end car hub manufacturing process is completely different from ordinary cars.Now the manufacturing process of aluminum alloy wheel hub on the car is mainly divided into casting and forging, we understand the difference between these two, we will understand why high-end models will prefer to use forged wheel!

1. What is the casting process for the hub?

First of all, the casting process, we may know that most of the current models of aluminum alloy wheel are casting, but there are three kinds of casting wheel manufacturing process, namely gravity casting, low pressure casting and spinning casting.

(1). Gravity casting is very simple, pour liquid metal into the wheel hub mould cooling molding is ok, this way of casting efficiency is very high, the cost is the lowest, but quality is bad, because hub parts distribution is not uniform, and the metal internal molecular density is lower, so the strength of the wheel is not high, after the collision is prone to fracture.

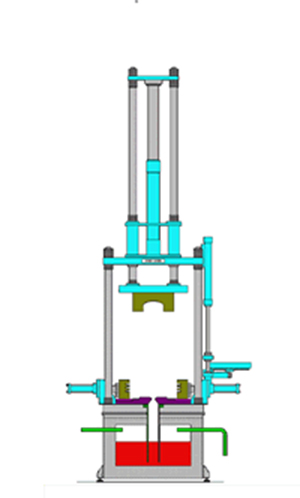

(2). Low pressure casting can be said to be on the basis of the gravity casting for an upgrade, after the liquid metal into the mold, the low pressure casting process will give it a constant pressure, so that the metal molecular density is higher, wheel molding after have higher strength, and low pressure casting process is very mature, so most of the models on the rim of low pressure casting process.

(3). The rotary die-casting process is to carry out a secondary processing of the cast hub, heating the hub while rotating stamping, so that the metal molecules in the hub will be more compact and the strength will naturally be higher.

2. What is the forging process of the hub?

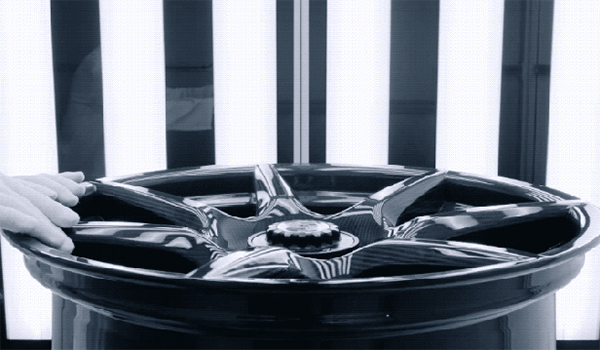

Said forging hub again, the manufacturing process of forging hub is aluminum piece of heated first, to a certain temperature with forging press pressure into blank then blank spinning forming, is equal to the casting wheel for higher intensity, and forging military grade aluminum wheel hub is used, the weight is lighter, forging hub can be further subdivided into one chip forging and multiple disk forging, a chip of the forging means the whole hub is a integrated, light weight and reliable.

And the multi - disc end to the rim and spokes separate, the advantage is that only replace the spokes can have a new hub style, but compared to the one - disc forging, multi - disc forging will be heavier, the assembly requirements are also compared.

3. Summary

From a high comprehensive point of view, because the forging hub production process is more precise, and higher strength, lighter weight, so that high-end models will use the forging hub, but in the replacement of the hub, there is no need to pursue forging.

Casting can be enough for everyone to use, and the price will be much cheaper, but don't consider unreliable gravity casting, low pressure casting or spin casting will be more reliable, general regular sales channels will be marked with wheel casting way, you can also use iron objects on the wheel hub, such as low pressure casting casting more clear voice to the proportion of force, but it needs to have certain experience

Post time: May-25-2020