Dear car enthusiast, have you ever been confused by the terms “forging” and “casting” when upgrading your running shoes for your beloved car? What secrets are hidden behind the huge price difference between them? Choosing improperly may not only result in wasted money, but also affect driving safety.

Today, NNX will become your hub consultant, using the most intuitive way to thoroughly understand the difference between forged and cast hubs, making you the hub expert among friends and making the wisest choice.

1️⃣ Core essence: The vast difference in manufacturing processes

To distinguish them, one must first understand how they were born. The differences in craftsmanship determine all of their characteristic differences.

Casting wheel hub – “one-time casting molding”, pouring high-temperature melted liquid aluminum alloy into a mold, cooling and solidifying it before molding. This is the most common and cost-effective manufacturing method. It is mainly divided into gravity casting and low-pressure casting (the latter has slightly higher density and strength).

Features: Efficient production, low cost, and versatile design options. But the metal molecule structure is relatively loose and may contain bubble impurities.

Forged wheel – the “elite of a thousand hammers and hundreds of refines”, uses a solid aluminum alloy billet to repeatedly extrude and forge under ultra-high tonnage (thousands or even tens of thousands of tons) forging presses.

Characteristics: The metal molecular structure becomes extremely dense, the fiber flow is uniform, and the strength and toughness are much higher than those of cast wheels.

2️⃣ 4 practical tips to help you easily distinguish

After understanding the essence, let’s learn how to distinguish truth from falsehood at a glance. You can make a preliminary judgment by “looking, weighing, touching, and listening”.

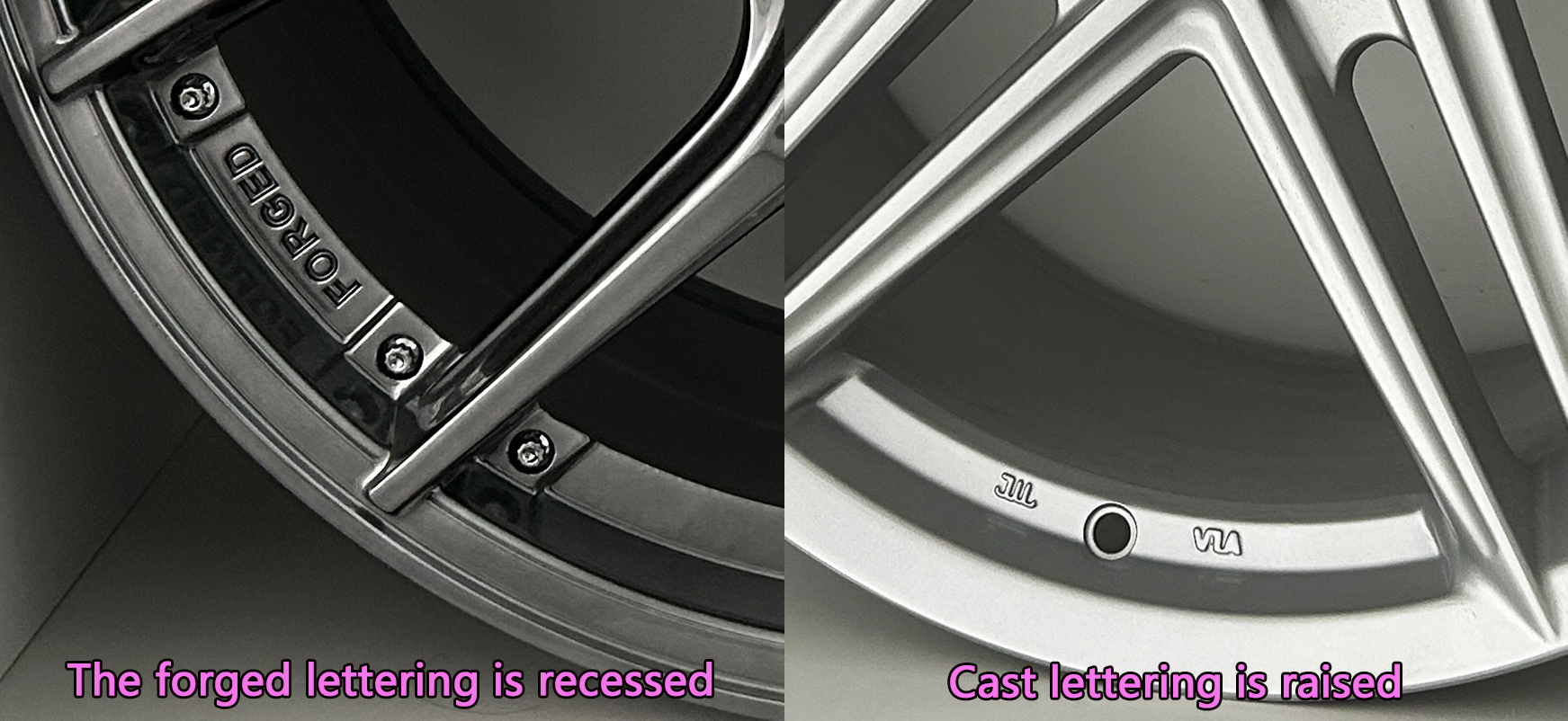

①Look at the inscriptions

Casting wheels is made by casting molds, and the characters are all protruding

Forged wheel are machined using CNC machines, and the characters are all recessed

②Comparative weight: Under the same design parameters, forged wheels are over 20% lighter than cast wheels.

③Look at the workmanship

The spokes of the cast wheel hub are thick, and some may show mold marks or burrs. There may also be small sand holes on the back

Forged wheel spokes can be made finer, resulting in a better overall texture

④Listen to the sound

Gently tap with a metal object (provided that the paint surface is not damaged), and the sound produced by forging the wheel hub will be clearer and louder, with a lingering sound similar to a bell. The sound of casting wheels is relatively dull and short.

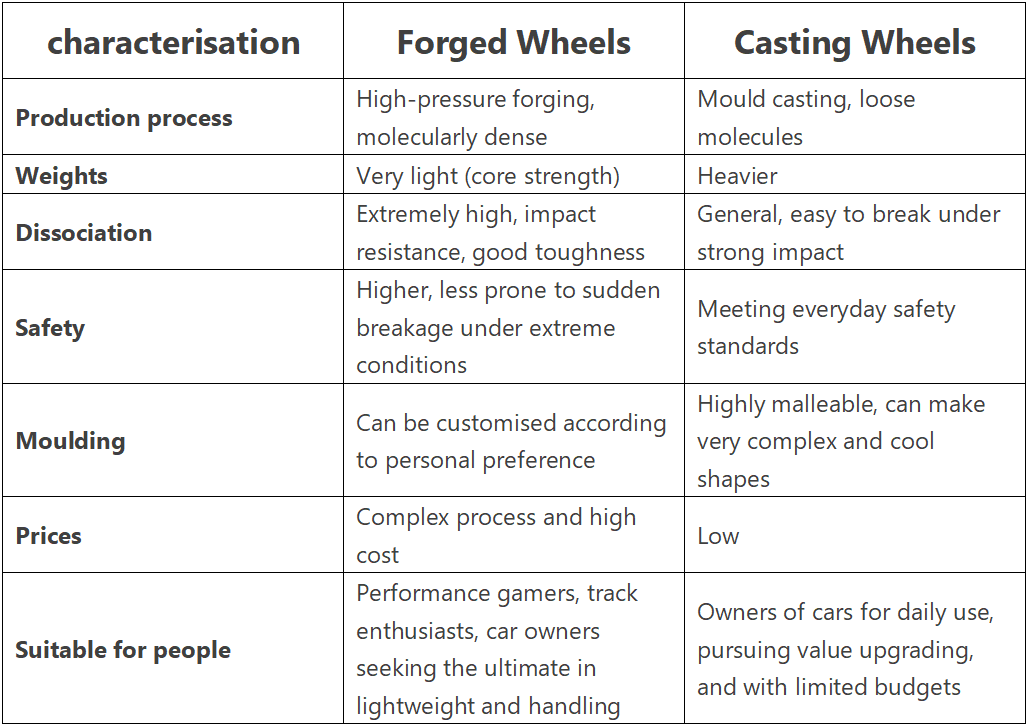

3️⃣ Performance Comparison Summary: How to Choose Based on Understanding a Picture

4️⃣ Provide your final purchasing advice

If you pursue ultimate performance, race time, lightweight, and highest safety, then “forged wheels” are your best choice. This is a worthwhile investment that can bring you a completely transformed driving experience.

If you pursue: aesthetic upgrade, personalization, high cost-effectiveness, meeting daily use → a high-quality “low-pressure cast wheel hub” is completely sufficient. Choosing a reputable big brand can also ensure safety and aesthetics.

Post time: Sep-04-2025