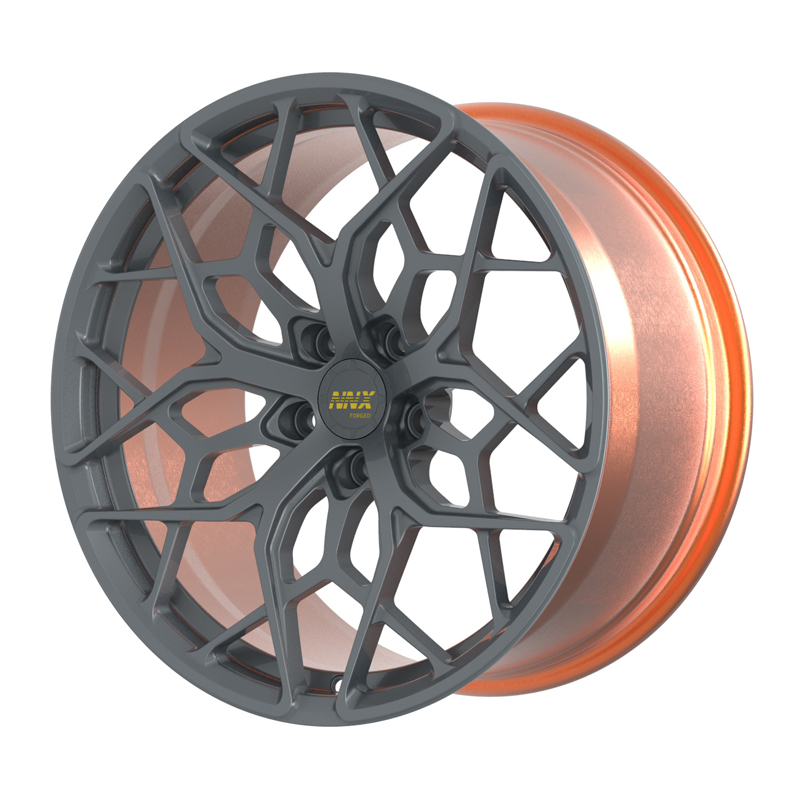

NNX-D1321 Monoblock forged matte black machined or custom 17 18 19 20 21 22 inch multi spoken forged wheel for refit

| Size | Width | ET(Offset) | Center bore(hub bore ) | Bolt Pattern(PCD) | |||

| 17 | 7J/7.5J/8J/8.5J/9J/9.5J/10J | You can customize any data and color you need. | |||||

| 18 | 7.5J/8J/8.5J/9J/9.5J/10J/10.5J | ||||||

| 19 | 8J/8.5J/9J/9.5J/10J/10.5J/11J | ||||||

| 20 | 8J/8.5J/9J/9.5J/10J/10.5J/11J/12.5J | ||||||

| 21 | 8.5J/9J/9.5J/10J/10.5J/11J/11.5J//12/12.5J/13J | You can customize any data and color you need. | |||||

| 22 | 9.5J/10J/10.5J/11J/11.5J/12J | ||||||

| 23 | 10J/11J | ||||||

| 24 | 10J/12J | ||||||

-

NNX-D2859 New design customization Forged Wheels 15 16 17 18...

-

NNX-D2840 Manufacturer Wholesale Best Selling Chinese Alloy ...

-

NNX-D733 5×120 Forged Aluminum 5×112 Car Wheel Pa...

-

NNX-D332 Made in China forging wheels car 16 17 18 19 20 21,...

-

NNX-D580 custom forged 18 19 20 21 22 inch 5×114.3 forge...

-

NNX-WD28 18 19 20 21 22 23 24 inch Forged alloy passenger ca...

32 color combinations available in our online store.

The Hybrid Forged Billet Sport Cap offers 32 combinations of colors to personalize your NNX Wheels. Starting as 6061 billet aluminum, the cap bezels are machined, hand- finished and powder coated in Vossen’s Miami-based factory using the same finishes as NNX Forged wheels.