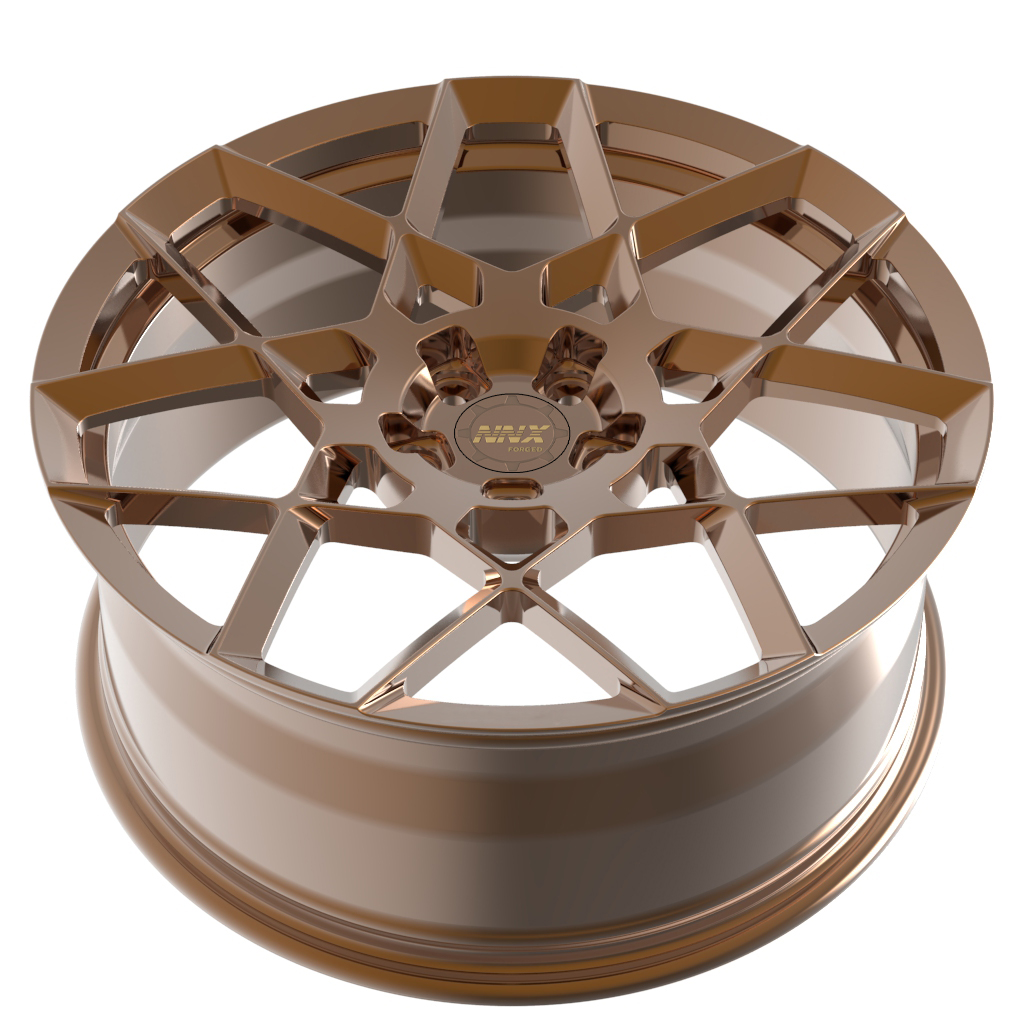

Forged Alloy Car Wheel Rims Customised Alloy Wheels High Quality Aluminium Alloy Rims 17~24 Inch

NNX-D67 20X9 ET 24 17 P.C.D 5X112 center hole 66.6 1piece forged wheel (custom 16-24inch and date)

Is the Is the thermal treatment process of large forging parts complicated? Generally, the thermal treatment of large forging parts is combined with the cooling of the forging parts, because the cross-section size of the large forging parts is large and the production process is complicated. In the process of thermal treatment, some forgeds are prone to white dot defects due to uneven tissue performance.

Therefore, in addition to eliminating stress and reducing hardness, the main purpose of large forging heat treatment is to prevent white spots on the forging parts, improve the uniformity of forging chemical composition, and adjust and refine the microstrip of forging.

-

NNX-D1123 Factory Outlet 17 18 19 20 21 22 23 24 Inch Blac...

-

NNX-D4011 Most popular style customised forged wheels high qual...

-

NNX-D475 Chinese custom wheels R15 R16 R17 R18 inch 19 inch a...

-

NNX-D768 Customized luxury monoblock 1 piece forged alloy wh...

-

NNX-D4178 5×120 Forged Aluminum 5×112 Car Wheel Pas...

-

NNX-D4212 High Quality Polished Aluminum 20 21 22 23 24 Inch 5...

32 color combinations available in our online store.

The Hybrid Forged Billet Sport Cap offers 32 combinations of colors to personalize your NNX Wheels. Starting as 6061 billet aluminum, the cap bezels are machined, hand- finished and powder coated in Vossen’s Miami-based factory using the same finishes as NNX Forged wheels.