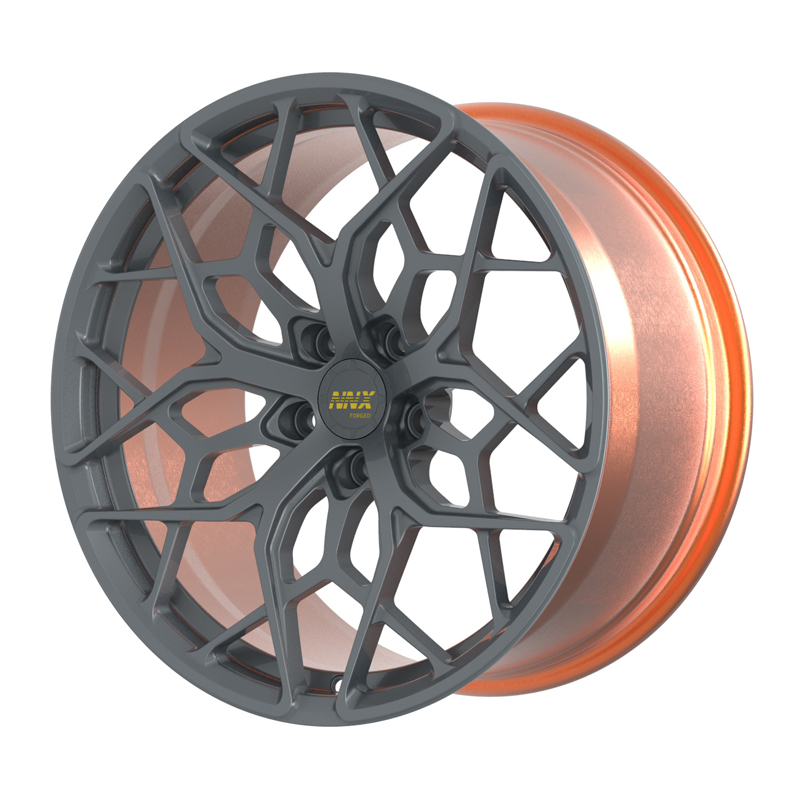

NNX-D893 Hot Sale Wheels Casting Alloy Car Rims Light Weight Cheap Wheel Rims

NNX-D893 22X10 ET 48 P.C.D 6X139.7 center hole 95 1piece forged wheel (custom 16-24inch any date)

The rotation method of automobile aluminum alloy wheels

The rotation technology is continuously extended during the rolling process through continuous rotation movement and squeezing under specific temperature and pressure. This process maintains the density of the metal and the dynamic balance of the entire wheel hub, making the wheels thinner, lighter, and more durable. The spinning wheels are kept enough. At the same time, the intensity can greatly reduce the thickness of the material. Compared with ordinary low-pressure cast aluminum wheels, the same size wheels can be reduced by about 15%. This technology is mainly used for the production of wheels such as racing, sports cars, and off-road vehicles, and is mainly used for the production of wheels such as racing, sports cars, off-road vehicles, large buses, and trucks. Together with forging technology, it can also be used for post-processing of corrupt technology.

1. Cold rotation process for aluminum alloy wheels

The rotation process of the wheels was originally limited to ordinary rotation. It is only suitable for processing materials with good plasticity and thin thickness. The size accuracy is not easy to control, and the technical level of the operator is high. In the middle of the 20th century, the spinning technology developed from ordinary spinning to strong spinning, and the application range expanded rapidly. Compared with ordinary rotation, the convex part of the blank has no shrinkage and deformation, so there is no wrinkles. The powerful rotation forming of the wheels is developed on the basis of the ordinary cylinder-shaped powerful bedding technology. The wheels of the car wheels are macated with powerful rotation, and the performance indicators of the wheels are greatly improved and can be used. With the development and improvement of metal plastic formation technology, the rotation has been widely used in the processing and production of car wheels. The aluminum alloy hub below the 17-inch (43.18cm) abroad uses a rotten forging or casting a rough type, which has become a mainstream production method. Compared with developed countries in the world, my country’s research in this area is relatively backward. In recent years, my country has achieved some research progress in the technology of aluminum alloy car wheels. By studying the effects of process parameters such as turning wheel shape, the speed of rotor feed, the decrease of the wall thickness, and the staggered distance between multiple turntables on the effect of the forming effect, the causes of the defects of surface instability, rotation and cracking, etc. Provide effective methods and basis for optimizing the process parameters of aluminum alloy turntables. On the basis of analyzing the 6061 aluminum alloy rotation of the forming performance, the process and effect of the symmetrical disk hub on the PT30501CNC two-wheel horizontal powerful presses were discussed. By selecting reasonable process parameters, the accumulation, peeling, cracking and other defects in the spinning process are solved. Abstract: A scanning electron microscopic analysis was performed by scanning electron microscopy on the A356 aluminum alloy wheel wheel wheel. It was found that these defects were shrinking holes formed in the solidification process, and prevention of prevention on the basis of system analysis of the mechanism of the shrinking hole formation mechanism was given to prevent prevention. measure. This article uses the rigidity finite element software DEFORM-3D to simulate the compression formation process of aluminum alloy hubs, and the effects of the effects of major process parameters such as differential decreases, feed speeds, and spindle speed on the formation process are analyzed. The combined process parameters are verified and the analysis results are verified through the pressure experiment, which provides theoretical guidance for the actual production of the rotary aluminum alloy wheels. The deformation mechanics model of the car hub rotation was established, and the finite element of the entire formation process of the wheels was used to simulate the entire formation process of the wheels. The laws and basis for effective process research and process parameter optimization were analyzed by analyzing the laws and basis of the deformation zone.

- Min.Order Quantity: 4 Piece/Pieces

- Supply Ability: 100000 Piece/Pieces per Month