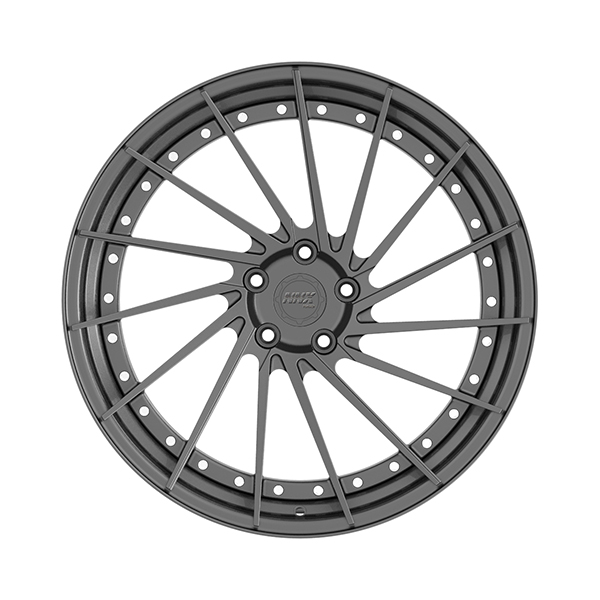

NNX-S244 19X9.5 20X11 ET 0 6 P.C.D 5X120 center hole 72.56 2piece forged wheel (custom 18-24inch any date)

How to repair these three injuries?

1. Repair on surface damage

Wheel surface repair

Common wheel damage is mainly abrasion and abrasions. The repair only treats the surface. Basically, it does not affect the main force structure of the original wheel hub, and has little effect on the reliability and safety of the wheel hub.

The repair steps are as follows:

Step 1, polishing:

Most of the wheels are treated with dust-free sandblasting, and then the details are polished with more delicate sandpaper. This part is a fine work, and patientness is important.

Step 2, apply putty:

After the wheels are polished, it is well understood to fill the scratch with alloy putty, which is the same as filling the scratch with the carrier with putty on the car sheet metal. Alloy putty is used on the wheels, which is harder and delicate than ordinary putty for car sheet metal.

Fix the second step: “putty”

This is not a putty for we paint, it is a special metal putty, also called sheet metal putty.

The names of different brands are slightly different. There are many types of putty, including plastic putty, glass reinforced reinforced earnestly, metal plate putty, and so on.

You can simply understand: this is a variety of “soil” for different materials.

Step 3, polishing:

After filling, polish excess uneven part with a corner grinding machine.

The putty needs to be used in conjunction with the corresponding curing agent. After finding the flat, it needs to be relatively polished to make it completely flat, which is convenient for subsequent paint. Of course, if your dentation is deep, you need to use aluminum welding to repair. Putty is mainly targeted at the least damage.

Step 4, painting:

After the surface is processed, it should be painted.

Painting is also the most technical step.

Step 5, draw:

If there is a wheel with a metal drawing process on the surface, it will fail with conventional polishing. Precision machining is needed to use the wheels to disappear until all scratches disappear.

Step 6, dry:

After the primer is dry, spray paint (facial paint, varnish, varnish) protection needs to be sprayed.

Finally, put it in the oven at high temperature and bake for 20 minutes.

Step 7, polishing:

The repair process of the wheels is basically over. In order to make the wheels look more new and beautiful, starting the polishing machine with thick fine abrasives to complete the wheel polishing.

2. Transformation repair:

When the car hub is hit or collided, it is easy to cause the wheels of the car’s hub to bend and deform, which is a serious damage.

The general process of this damage repair is: deformation position detection-heating-correction-completion. However, the wheels are made of aluminum alloy, and the anti -metal fatigue is poor. After being deformed by external forces, it was forcibly restored by external forces. Even if there are tiny cracks on the surface, from a scientific perspective, the metal structure here is completely different from normal wheels.

- Deformation position detection: First find the deformation position of the wheel hub, install the wheel hub on the fixture, and use the calibration scale disk to find the deformation position for calibration.

- Heating: Use a lamp to perform local heating to the deformation site. The small red dots on the wheels are infrared thermometers, which can stop heating when reaching a certain temperature.

- Correction: After reaching a certain temperature, the wheels become soft, and the small hydraulic pound is repeatedly corrected. Finally, achieve reasonable standards.

Three: The wheels are broken

This hub is the most damaged. Although the wheel break can be repaired by welding, the safety performance is greatly reduced.

The normal wheel manufacturing process is cast. It is cooled or crystallized under the action of melt. Welding is a process of local heating, melting, and solidification. However, welding stress must be performed around the weld. After a period of load running, it is likely to cause fatigue cracks in the high stress area of the wheel hub, causing serious consequences. Therefore, if the wheels are broken, it is not recommended to repair it, and it should be replaced directly. After all, the wheels are safety parts, which has a great impact on safety driving.