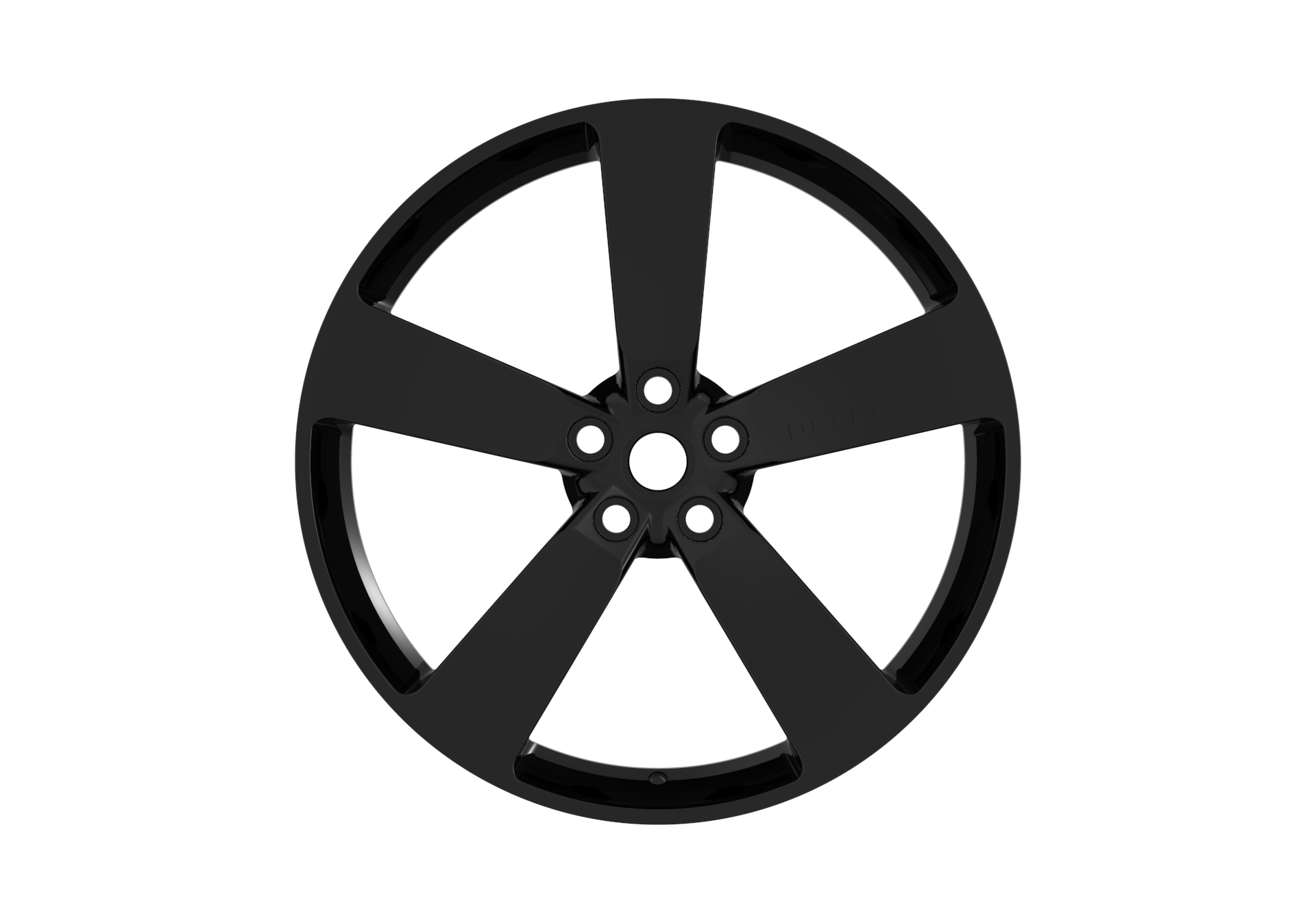

Factory sales21 22 inches alloy car rim, 5X112 5X130 alloy car wheel rims

SIZE OFFSET RANGE PCD RANGE

Product image shown not representative of all configurations. Vehicle specific fitment will change offset, dish and center profile. Please consult your salesperson for application-specific details.

| Size | Width | ET(Offset) | Center bore(hub bore ) | Bolt Pattern(PCD) | |||

| 17 | 7J/7.5J/8J/8.5J/9J/9.5J/10J | You can customize any data and color you need. | |||||

| 18 | 7.5J/8J/8.5J/9J/9.5J/10J/10.5J | ||||||

| 19 | 8J/8.5J/9J/9.5J/10J/10.5J/11J | ||||||

| 20 | 8J/8.5J/9J/9.5J/10J/10.5J/11J/12.5J | ||||||

| 21 | 8.5J/9J/9.5J/10J/10.5J/11J/11.5J//12/12.5J/13J | You can customize any data and color you need. | |||||

| 22 | 9.5J/10J/10.5J/11J/11.5J/12J | ||||||

| 23 | 10J/11J | ||||||

| 24 | 10J/12J | ||||||

-

NNX-D708 good quality 1-piece full painting silver brushed 1...

-

Manufacturer Wholesale China Matte Black Faced-Machined 16 17 1...

-

NNX-D950 2021 New Aluminium 18 Inch Wheels 5X120 19 Inch Al...

-

NNX-D5494 for luxury cars New best price customised 18 19 20 ...

-

NNX-D2237 Personalized Color customized Brushed Sliver 19*8....

-

NNX-D1446 Customizable 18 19 20 Inch Digital Disc Shaped Alloy ...

32 color combinations available in our online store.

The Hybrid Forged Billet Sport Cap offers 32 combinations of colors to personalize your NNX Wheels. Starting as 6061 billet aluminum, the cap bezels are machined, hand- finished and powder coated in Vossen’s Miami-based factory using the same finishes as NNX Forged wheels.